PA / Nylon Filament

8 products

Showing 1 - 8 of 8 products

Collection Description

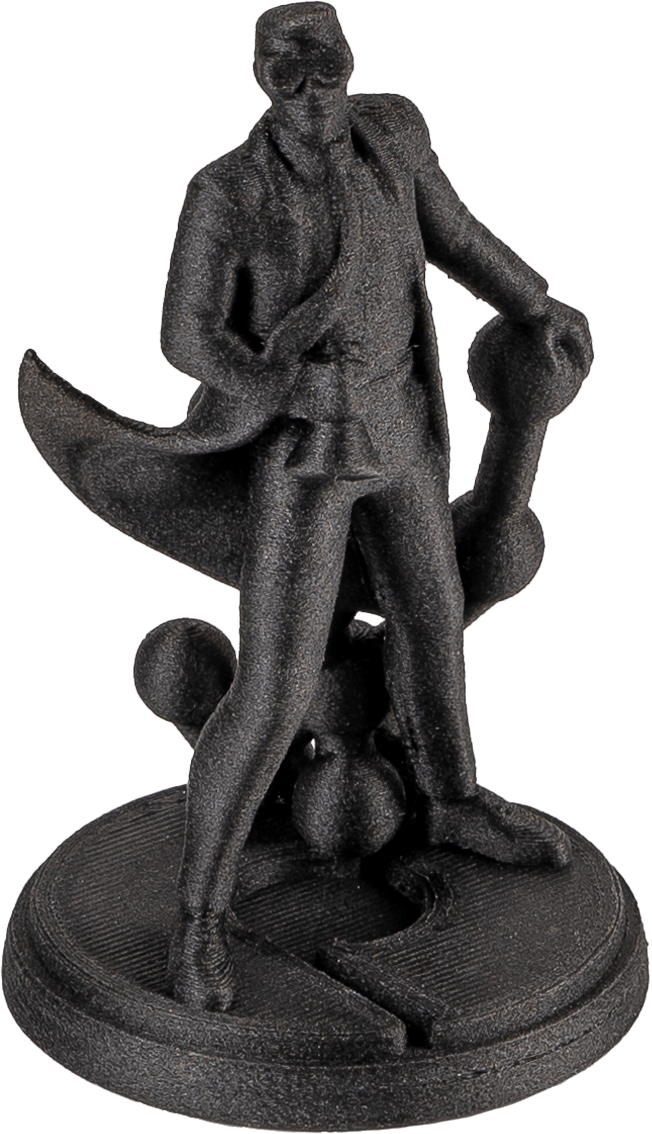

PA/Nylon filament is renowned for its exceptional strength, some flexibility, and durability, making it a top choice for various applications that demand high performance. This material exhibits excellent resistance to wear, high temperatures, and most oils and greases, ensuring your prints withstand the rigors of mechanical stress and environmental challenges.

Are you feeling overwhelmed by choices? Need assistance selecting the best materials for your next project or product? Reach out to us! We’re happy to recommend the most suitable materials to meet your specific needs and ensure your project’s success. Feel free to contact us for personalised suggestions!

Key Features of PA/Nylon Filament

-

High Strength and Flexibility: PA/Nylon is designed to handle stress and strain without compromising on flexibility. This characteristic makes it suitable for components that must endure dynamic loads and repeated use. Annealing or coating may be required for some blends such as PA6 as those are moisture prone and can creep under load when to annealed.

-

Wear Resistance: The inherent toughness of Nylon makes it resistant to abrasion, ideal for mechanical parts that encounter friction and wear over time.

-

Temperature Resistance: With the ability to maintain performance in high-temperature environments, PA/Nylon is perfect for applications where thermal stability is essential. Its recommended to annealing nylon for better temperature performance or opt for PPS or PPA which as better stability straight from the a print but annealing will improve nylon stiffness and temperature resistant. .

Specialty Blends

At DREMC, we offer a diverse range of PA/Nylon blends to cater to specific needs:

-

GF (Glass Fiber) Blend: This blend enhances the mechanical properties of standard Nylon, providing increased rigidity and strength. It's perfect for printing complex geometries that require added load-bearing capabilities.

-

CF (Carbon Fiber) Blend: Combining Nylon with carbon fibers results in an ultra-strong and lightweight filament. This blend is ideal for applications requiring high performance with minimized weight, such as automotive and aerospace components and improve weatberablity.

-

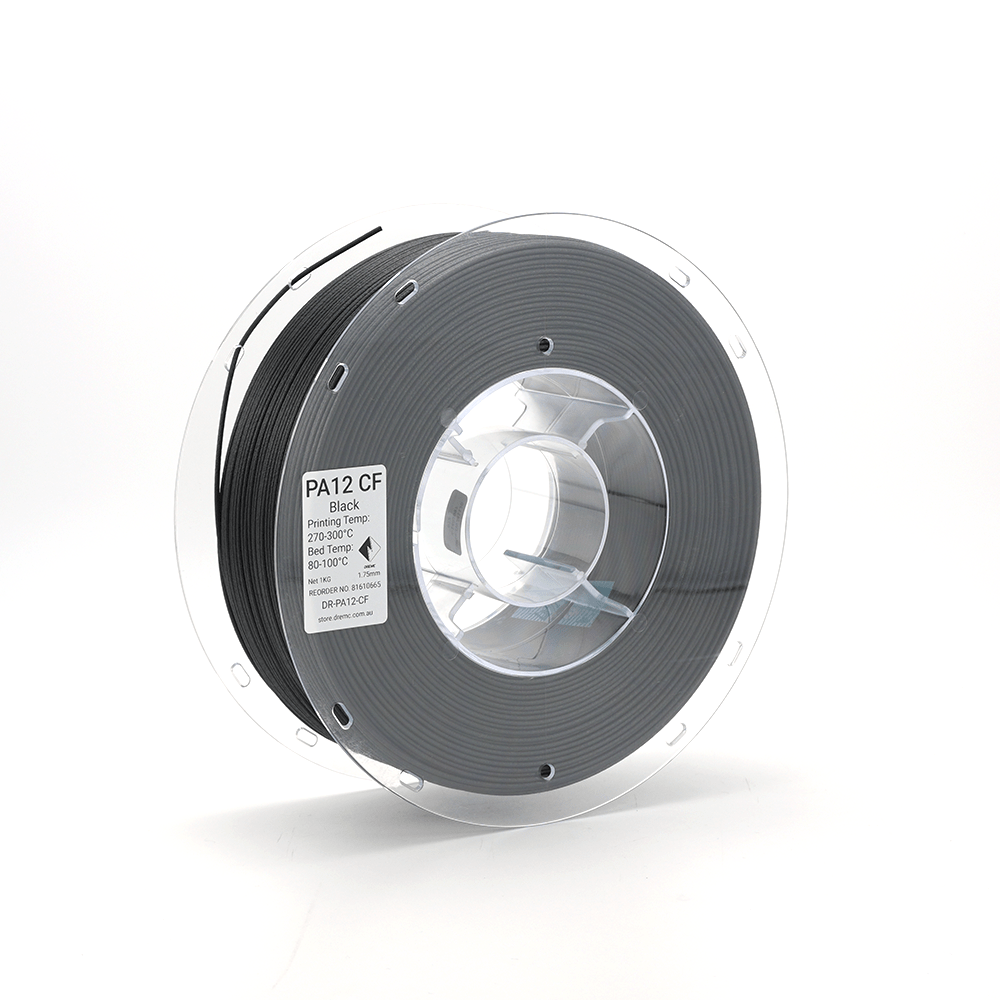

Popular PA12: Known for its balance of strength and flexibility, this versatile blend is suitable for a wide array of applications, from functional prototypes to end-use parts. Less prone to moistures but slighty less temperature resistant.

-

PPS/PPA Blends: This blend offers exceptional thermal stability and chemical resistance, making it ideal for specialised applications in harsh environments but require higher industrial printing requirements (300+c Nozzle and Active Chamber)

Ideal Applications

Our PA/Nylon filament is suited for:

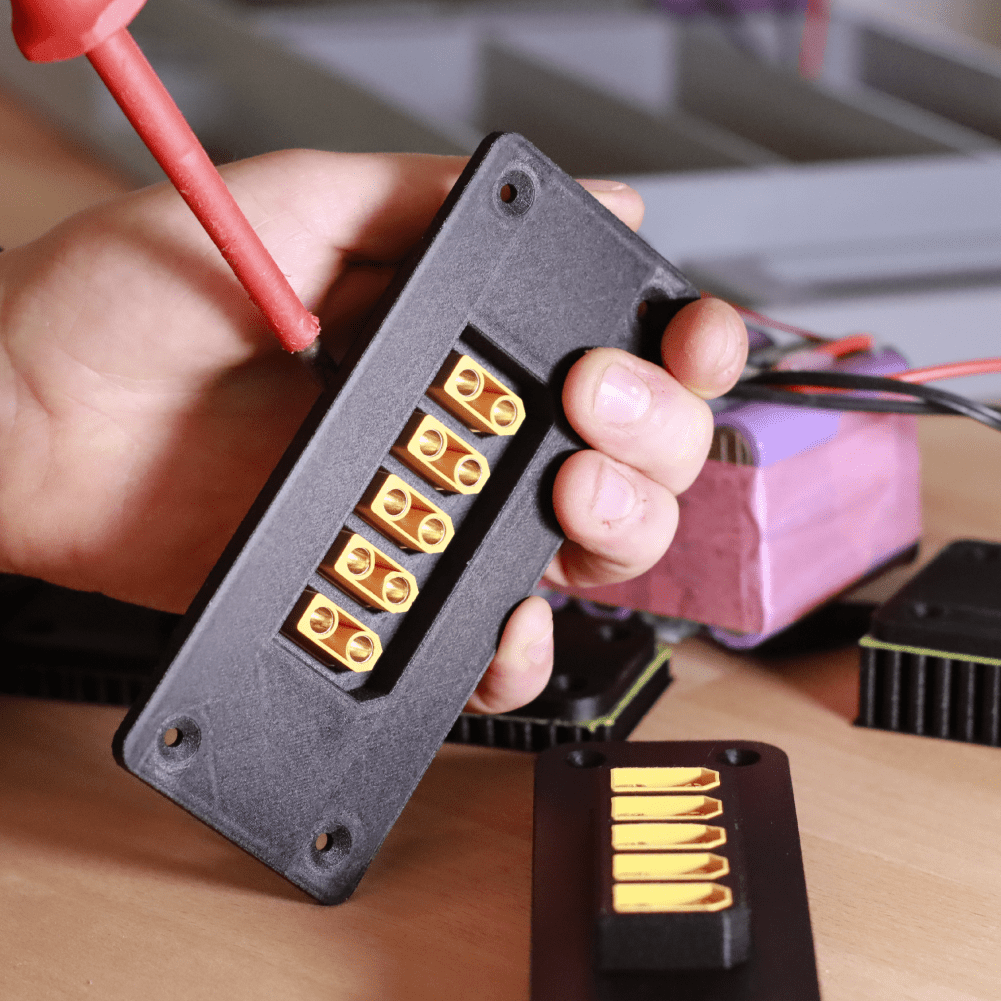

- Mechanical Components: Create durable gear systems, bearing housings, and other parts that require resilience and performance.

- Jigs and Fixtures: Design custom tools that can handle repeated use without wear or failure. (Some materials will require annealing to be used in static medium/long term loads)

- End-Use Applications: Reliable parts that meet industry standards for functionality and performance across various sectors, including automotive, aerospace, and manufacturing.

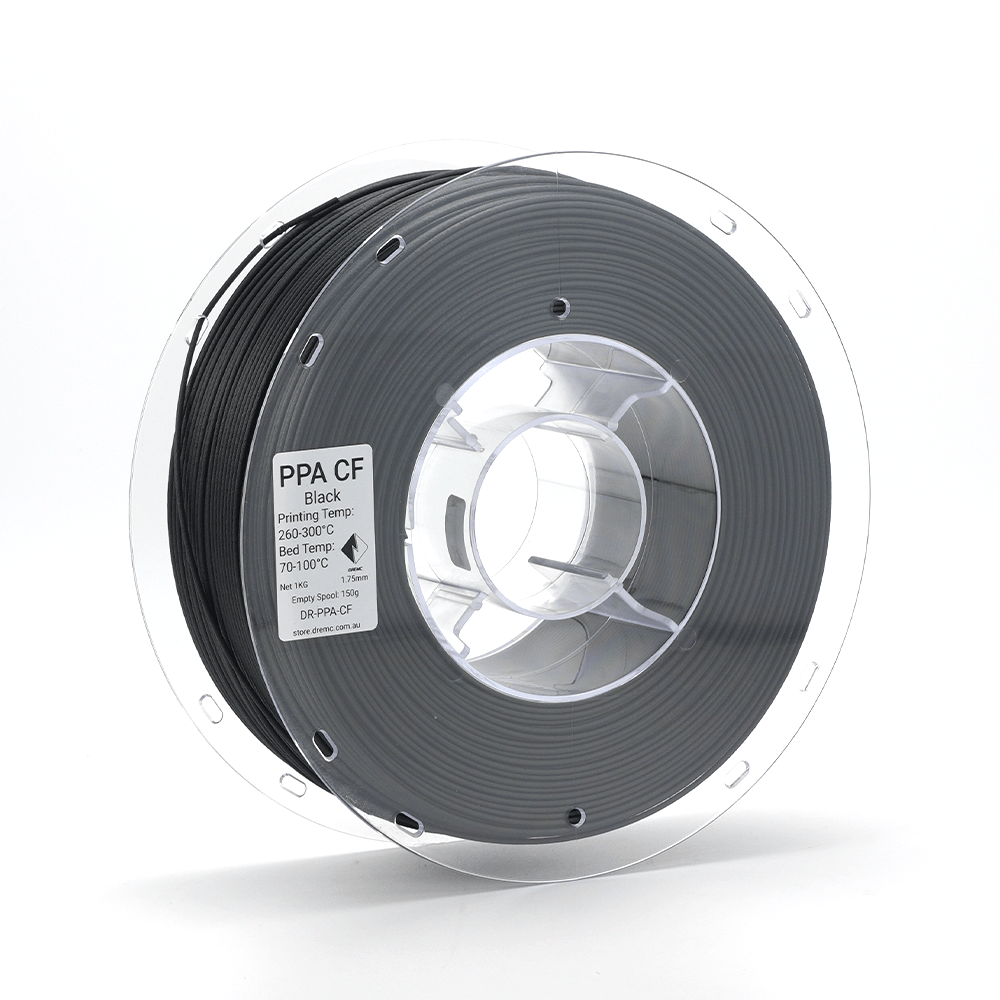

DREMC PPA CF Carbon Fibre Filament 1.75mm 1kg

DREMC PA12 CF Filament 1.75mm 1kg

Polymaker Fiberon™ PA6-GF25 500g 1.75mm (Formerly PolyMide™ PA6-GF)

Polymaker Fiberon PA612-CF15 Nylon 500g 1.75mm (aka PolyMide)

Polymaker Fiberon™ PA612-ESD 500g 1.75mm