Understanding Fibre Reinforced Filaments

Reinforced 3D printing filaments have become a favourite in the industry for creating high-strength prints. Similar to how rebar strengthens concrete, adding specific materials to a 3D printed part enhances its structural integrity, resulting in greater stiffness and dimensional stability. Various additives, such as carbon nanotubes, Kevlar, and ceramics, have been utilised in 3D printing filaments. However, chopped/milled carbon fiber and glass fiber are the most commonly used reinforcements. Both offer improved performance over standard filaments, but how do you decide which is best for your 3D printing project? At DREMC, we’ll explore the differences between glass fiber and carbon fiber filaments to help you make an informed choice.

What is Carbon Fibre Reinforced Filament?

Carbon fibre reinforced filament, is renowned for its superior stiffness and high strength-to-weight ratio. While the stiffness of carbon fibre is advantageous, it can also lead to brittleness. In technical terms, carbon fibre-filled materials require more energy to fracture than unfilled versions, although the nature of the fracture can be more pronounced.

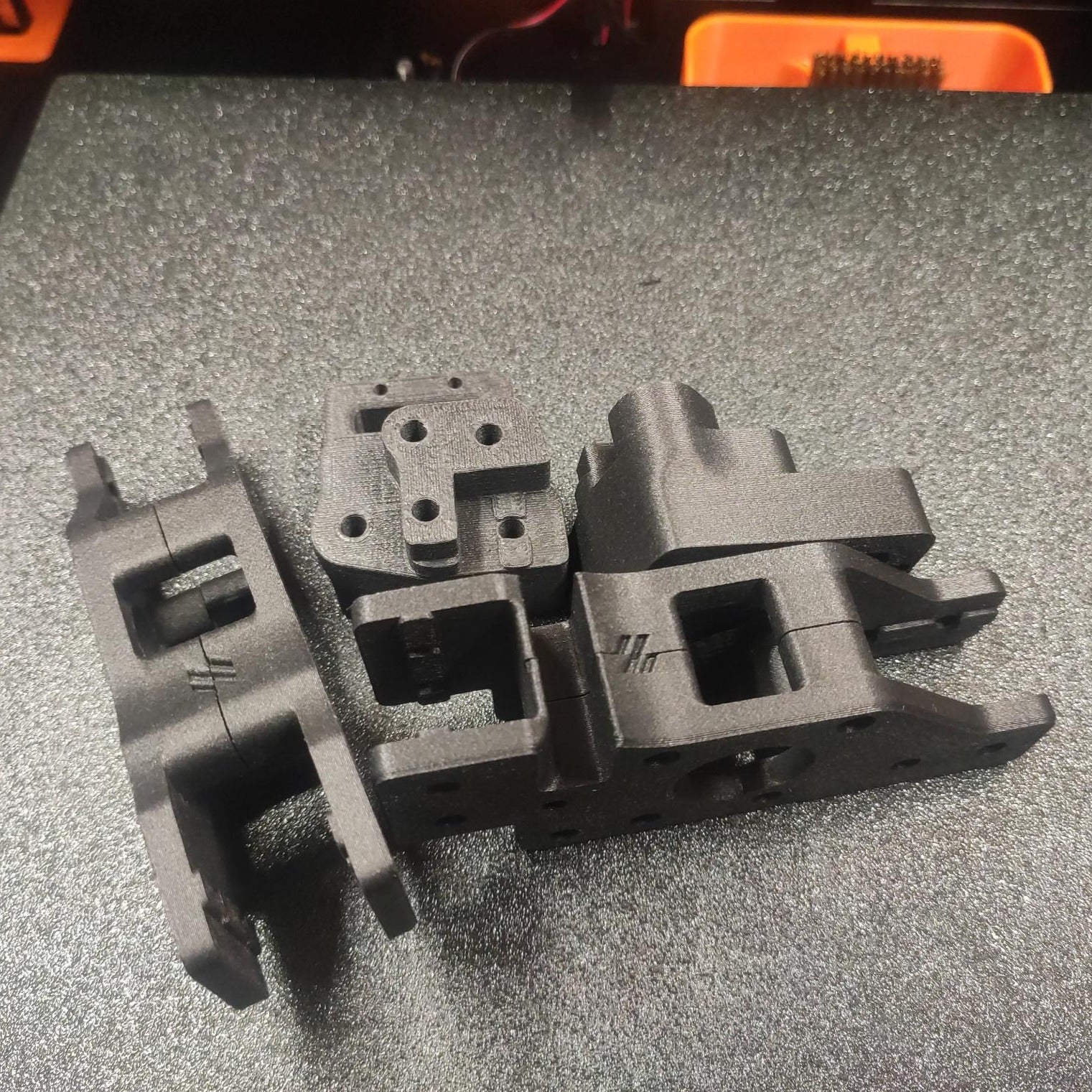

Filaments reinforced with carbon fibre are lighter than their glass fibre counterparts and provide excellent dimensional stability, which is crucial for precision applications or more shrinkage prone materials. For example, traditional ABS has a cooling shrink rate of about 0.5%, while carbon fibre ABS shrinks only about 0.1%. This reduced shrinkage means that your parts will be more true to the original design and less printing issue such as warping. Carbon fibre-filled filaments, such as our chopped CF/GF line, are ideal for lightweight yet robust parts, such as those used in drones or automotive applications. However, the enhanced performance comes with a higher price and increased abrasiveness, necessitating the use of hardened steel nozzles for printing.

It’s important to note that 3D printed carbon fibre parts differ from traditional carbon fibre components. Conventional carbon fibre production employs continuous fibres to maximise strength, whereas carbon fibre filament consists of chopped fibres designed to improve rigidity and reduce weight. You would need system like MarkerForge or Anisoprint system for continuous fibre which can dramatically improve X/Y plan strength further without minimal layer adhesion impacts.

What is Glass Fiber Reinforced Filament?

Glass fibre is a lightweight and durable material employed across multiple industries. Traditionally used in applications like boat hulls, automotive bodies, and construction panels, its durability and cost-effectiveness make it ideal for large-scale, high-stress environments. In additive manufacturing, glass fibre is incorporated to enhance the strength and impact resistance of printed parts. These characteristics make glass fibre filaments suitable for components exposed to extreme stress and wear. Additionally, glass fibre filaments tend to be more affordable than carbon fibre options, making them an attractive choice for budget-conscious projects. However, they lack the stiffness that carbon fibre provides.

A standout feature of glass fibre filaments is the wide array of colour options available. Unlike carbon fibre, which possesses a dark inherent colour and cannot be dyed, glass fibre filaments are offered in various hues. This versatility is especially important for applications where aesthetics matter, allowing users to match brand colours or enhance the visual appeal of their finished products. For instance, our glass fibre is available in vivid colours, all while maintaining the strength and durability expected from reinforced filaments. We also offer customised colour avaaible to match your company colour (available on request)

Key Differences: Strength, Weight, and Cost

When evaluating strength, both carbon fibre and glass fibre additives significantly enhance the durability of your prints. Glass fibre excels in flexibility, while carbon fibre provides greater stiffness. The lightweight nature of carbon fibre gives it an edge in applications requiring weight savings, but glass fibre is preferable for applications demanding toughness. Regarding cost, glass fibre reinforced filaments are generally more affordable, making them a sensible choice for functional parts on a budget, while carbon fibre is often reserved for high-performance applications.

Choosing Based on Application Needs

The optimal reinforced filament for your project hinges on the specific properties you require. If your application will face heavy impacts or stress, glass fibre filaments are likely the right choice. They are particularly effective for mechanical parts, enclosures, and tools that must withstand severe conditions. Conversely, if your project demands maximum rigidity and minimal weight (such as in aerospace or automotive), carbon fibre will offer you the performance you need.

Making the Right Choice

Both glass fibre and carbon fibre filaments have unique strengths, but your decision should reflect your specific printing requirements. If you prioritise flexibility and affordability, glass fibre is your go-to option. If you need high stiffness and lightweight characteristics, then carbon fibre is the superior choice. Regardless of your selection, DREMC provides a large catalogues of carbon fibre and glass fibre filaments, enabling you to produce stronger, more durable parts than with standard materials.