If you're exploring the differences between PETG and PCTG, you're in the right place. This guide outlines their key performance attributes—such as strength, durability, and chemical resistance—to help you choose the ideal 3D printing filament for your upcoming high-demand projects.

Selecting the right material is crucial in additive manufacturing. Among the popular choices for FDM printing are PETG (polyethylene terephthalate glycol-modified) and PCTG (polycyclohexylenedimethylene terephthalate glycol-modified). Both filaments are often compared for their durability, printability, and versatility across various 3D printing applications. While PETG is well-established in the 3D printing community, PCTG is gaining traction as a more robust alternative for parts that require greater performance than standard PETG can provide. If you’re curious about what sets PCTG apart, we’re here to clarify and help you understand its advantages.

At a molecular level, both PETG and PCTG are classified as glycol-modified polyesters, but they differ in the specific glycol used. PETG can incorporate either CHDM (cyclohexane dimethanol) or NPG (neopentyl glycol) to enhance clarity and reduce brittleness. In contrast, PCTG contains a higher concentration of CHDM—often exceeding 40%—which significantly boosts its impact resistance, ductility, and chemical resilience. These molecular distinctions make PCTG a superior option for engineering and functional components, especially those subjected to mechanical stress and harsh environments. This scenario is similar to comparing ASA to ABS, where ASA provides similar ease of printing but excels in weatherability and UV resistance, making it better suited for outdoor or demanding applications. Although both filaments belong to the PET family, PCTG is frequently viewed as the next-generation upgrade, offering enhanced toughness without sacrificing the ease of printing characteristic of PETG.

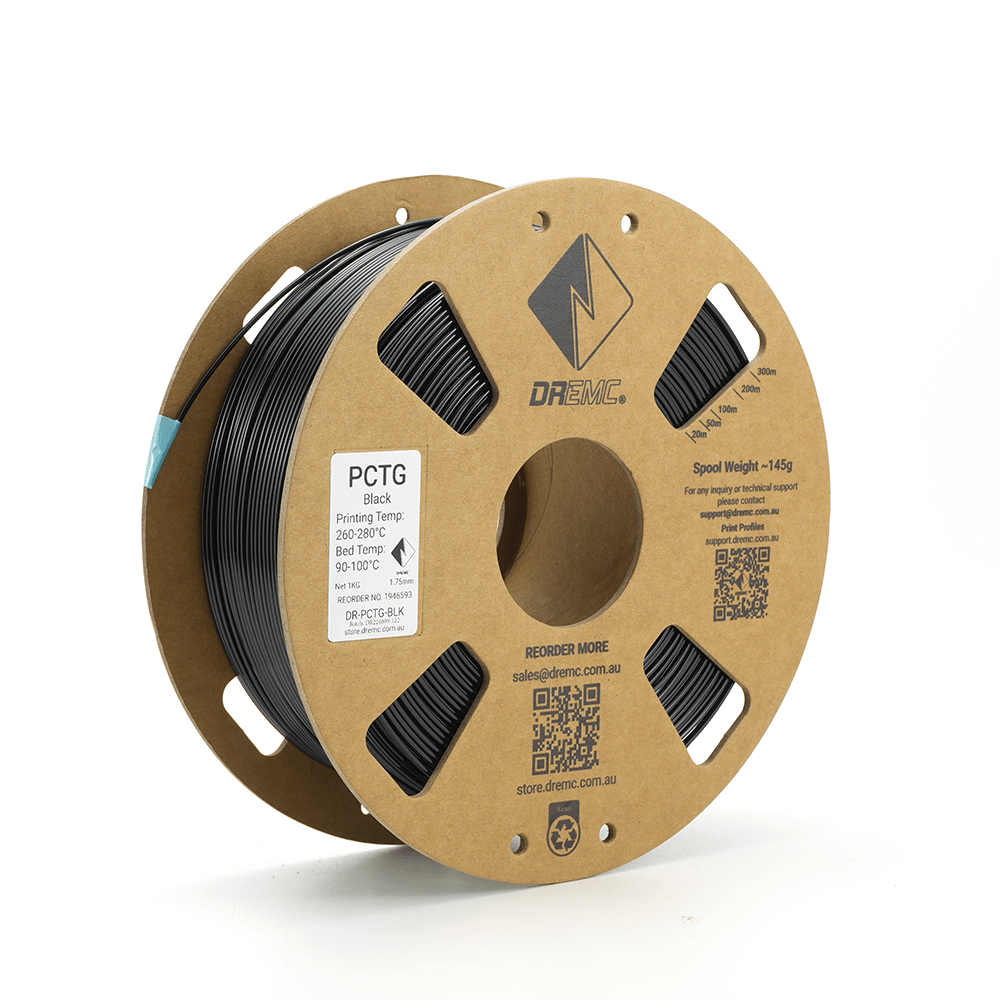

In terms of performance, DREMC’s PCTG demonstrates clear advantages over standard PETG filaments. Both materials exhibit comparable tensile strength (40 vs 45 MPa) and flexural strength (~65 vs 75 MPa) with PCTG offer both better tensile/flexural strengths. This makes it an ideal choice for performance-centric components. With a wide processing temperature range (250–270°C), low moisture absorption, and minimal printing odour, PCTG is compatible with most open-source desktop 3D printers—providing an engineering-grade, performance-minded upgrade to PETG accessible to a broader user base.

Chemical and thermal resistance are also key differentiators between these materials. PETG is already favoured for its superior chemical resistance compared to ABS, but PCTG takes it a step further, able to withstand exposure to certain solvents and cleaning agents, including isopropyl alcohol, without deterioration. Furthermore, it maintains a comparable with slightly higher HDT temperature (ISO 75 / 0.455 MPa) (~74°C), ensuring thermal stability in various operational conditions. Both materials are recyclable, but PCTG’s enhanced mechanical properties make it more suitable for applications where part longevity, safety, and consistency are critical. In engineering-grade contexts, PCTG’s combination of toughness, ductility, and chemical resistance makes it the preferred choice for applications where failure is not an option.

In the rapidly evolving realm of 3D printing, material innovation is key to maintaining a competitive edge. By embracing advanced materials like PCTG, professionals and engineers can achieve higher mechanical performance without compromising the printability and versatility typically associated with PETG. Whether you're developing functional prototypes, jigs and fixtures, or end-use components, PCTG offers the toughness, chemical resistance, and dimensional stability that surpass what PETG can deliver. For those at the forefront of filament technology, PCTG is not merely an alternative; it’s an essential upgrade for your additive manufacturing process.

That said, PETG continues to be a reliable filament for a range of prototyping and low-stakes applications. If your project doesn’t require the enhanced toughness or chemical resistance PCTG provides, DREMC’s modified PETG remains a trusted performer. Additionally, for specialised engineering requirements, DREMC offers various filled PETG options, including PETG+CF / PETG+GF for increased stiffness. Whether you need a dependable standard filament or a solution tailored for a specific challenge, DREMC has performance-driven filament options to meet your requirements.