Original Source: https://e3d-online.com/blogs/news/revo-heatercore-features

L;DR: We discuss the thinking behind Revo, and explore the Revo HeaterCore – what it is, how it works, and how it fits in with our plans.

New hotness

Have you heard? Throughout 2020 and 2021 we’ve been busy developing a completely new heating and sensing architecture for our brand new Revo ecosystem. We’ve called it ‘the Revo HeaterCore’, and it’s designed to improve on existing 3D printing heating and sensing technology in a number of ways – including rapid heat-up times, better safety, and the end of hot tightening!

Strap yourselves in: this blog discusses the thinking behind Revo, and an exploration of the Revo HeaterCore – what it is, how it works, and how it fits in with our plans.

The RapidChange Revo ecosystem from E3D

Why re-invent the HotEnd?

At E3D we want to produce technology that will have the biggest impact on human progress. That’s why we target improving things like the accessibility and user experience of extrusion systems.

We refer to E3D V6 as an ecosystem because we’ve made different compatible nozzles, heaterblocks, and heatbreaks available for it over time. However, V6 wasn’t originally designed as an ecosystem – it developed into one, with compatible parts added later that had to accommodate the original design.

Revo is different. It’s been designed and developed as an ecosystem from the very beginning. This puts us in a better position to solve the hang-ups and limitations we noticed with maintaining the V6 ecosystem. (Don’t worry, V6 isn’t going anywhere – we’ll continue to support and sell the V6 ecosystem as long as people want it. We even have a new V6 nozzle in the works.)

The Revo advantage

Besides faster heat up times, another big advantage of the new Revo system is how easy it is to use. Changing a Revo Nozzle doesn’t need heat, tools, experience, or complex documentation. User interaction is intuitive – just screw in a Revo Nozzle finger-tight, and you’re ready to 3D print. The continuous heatbreak-to-nozzle geometry means you don’t need to worry about the joint in the heaterblock to seal – it’s done for you during production with heavy-duty equipment, making it virtually leak-proof. Plus, Revo is compliant with Reach, RoHS, and WEEE standards.

Brass Revo Nozzles will be available at launch, and we’re already working on a wear-resistant ‘ObXidian’ Revo Nozzle that will release later this year, so you can print advanced composites without causing any wear.

All Revo products are compatible with 1.75mm filament and come with 12V or 24V power ratings, as these are the dominant specs in the market. Of course, if you’re an OEM looking to bulk-buy custom Revo parts to integrate into your machine, we can always talk.

Common 3D printing problems solved by Revo

No more tools

How many people reading this have workbenches cluttered with custom nozzle-changing wrenches or M6 hex bits? You won’t need these with Revo – you can do everything using your fingers! Even if you have limited dexterity.

Does this look familiar? (📸 Comedian, Discord)

No more hot tightening

To replace the nozzle for an E3D V6, an E3D V6 clone, or any other HotEnd on the market, you need to hot tighten a new nozzle to the heaterblock, otherwise the nozzle will leak at the joint when it’s printing because of thermal expansion. This is a finickity, hazardous process that is left completely up to the user to do, and it can go wrong. On our endless quest to refine FFF 3D printing HotEnd technology, we no longer feel it’s appropriate to expect users to do this.

What if a 300℃ brass nozzle lands in your lap when it comes loose? How many people reading this have crispy-bacon fingers from touching too much hot metal during these nozzle changes? It’s not ideal to expect a user to do this kind of task.

One of the more creative hot tightening methods (📸 ShadowBunny, Discord)

Fewer 3D print fails

If the joint between the heatbreak and the nozzle isn’t completely sealed, filament can seep out of the wrong places during a print, reducing extrusion pressure, creating molten plastic blobs around your heaterblock, and causing all kinds of frustrating print-failing-issues that will quickly have you throwing your 3D printer out the window in a rage and publicly denouncing the manufacturer on Twitter.

Improved compatibility for manufacturers

We sell to manufacturers who embed E3D tech in their machines. There have been instances where companies who partner with us won’t mention or support nozzle changing – even when it’s technically possible to do – because they consider the hot tightening process too complex and hazardous for their customers.

Reducing hazards with thermal runaways

Heaterblocks had a tendency for sensors to dislodge and fall out mid print. This means rather than sensing the heat of the heaterblock, they sensed the temperature of the air in the room, which is obviously much lower.

An E3D V6 heaterblock, heater, and sensor

The printer’s firmware would then interpret this as a signal to apply more heat to the heater, causing it to heat, and heat, and heat, so it reaches insane temperatures – much higher than the melting point of aluminium, which heaterblocks are often made of.

A lot of 3D printers run firmware with thermal protection algorithms built in to counteract thermal runaways. The problem: people (and even some manufacturers!) disable them.

A Revo HeaterCore provides a fail-safe solution at the hardware level. It’s designed with a positive temperature co-efficient (PTC), so power to the heater decreases as it gets hotter, reducing hazards in the event of a thermal runaway. Besides this, the heater and sensor are potted in ceramic compound and wrapped in a silicone sock, so it’s far less likely anything will come loose.

The E3D Revo HeaterCore is an integrated heating and sensing architecture

No more crushed wires

Have you ever had a long print interrupted by a mintemp error because of faulty sensor wiring? Wiring looms can be fragile things, and stress and strain on wiring can be detrimental to your printer’s reliability. Our wiring looms are the highest quality: Each Revo HeaterCore has a stainless steel strain relief for robust mechanical reinforcement, and wires are braided and terminated with Molex microfit3 2 pin horizontal connectors. Plus we supply a terminated 1m cable to connect to your 3D printer’s mainboard.

Better uptime

When your machines aren’t doing what they’re supposed to do, it’s frustrating – particularly if you’re on a deadline. If the hot tightening process has been skipped or performed incorrectly, your HotEnd is going to leak. Or maybe you’ll snap a heatbreak while hot tightening it. Frustrating. Especially if you don’t have spares on hand – that means machine downtime, and that costs you.

If a Revo Nozzle should clog, just swap out for a new one in seconds. We’re selling them in fully loaded multipacks, so besides spares, you’ll have a variety of different sizes to explore.

Intuitive use

Cold nozzle changes without tools or hot tightening. The use of Revo is so intuitive, documentation is minimal. (It's already available in the E3D Help Center!)

Explore the RapidChange Revo ecosystem

How the Revo HeaterCore works

Revo has taken a classic HotEnd assembly and rebuilt it from the ground up. Here’s what it consists of:

A heatsink and fan. A Revo-compatible cold side has the same function as a typical heatsink, but there’s a small spring retention feature at the bottom to attach the retaining spring for a Revo HeaterCore.

Revo cold sides: Hemera, Micro, Six, and Voron

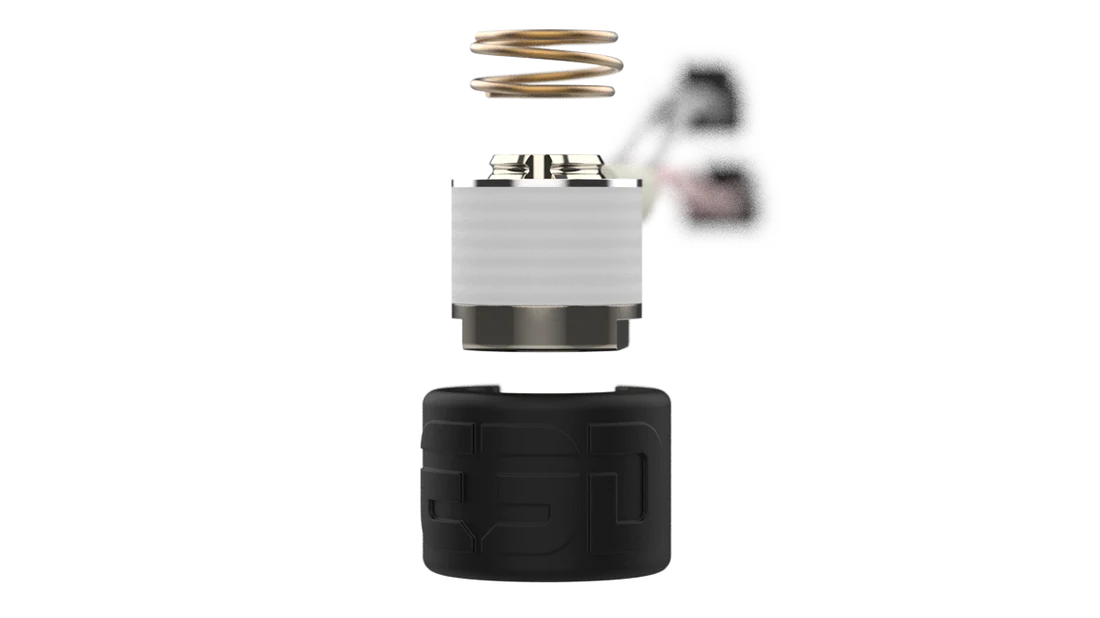

A Revo HeaterCore has a retaining spring that hooks around a lip on the bottom of the heatsink

A Revo HeaterCore. This replaces the heaterblock, heater, sensor, and fasteners altogether. It’s more compact, it’s easier to manufacture (we do it in-house!) and it’s wrapped in a silicone sock to keep the temperature consistent, keep residue out, and protect you from burns.

A Revo Nozzle. A Revo Nozzle slides through the middle of the HeaterCore and up into the heatsink. It screws into place and the retaining spring keeps the HeaterCore under tension for good thermal conductivity. A Revo Nozzle is a nozzle and heatbreak in a single factory-sealed assembly, so the user is no longer responsible for hot tightening. This means you can get up and running with fewer setup hassles and better reliability than a conventional nozzle – hooray! You can read more about Revo nozzles here.

Formnext 2021, Frankfurt: Demonstrating the speed and ease of Revo Nozzle changes in the #RevoRace!

Manufacturing a Revo HeaterCore

The heater

At first glance, it may look like another circular heater, but the process to make a Revo HeaterCore is quite different from currently existing heater technology.

Cheap heater cartridges like you might find on AliExpress are made by winding nichrome wire around a core, known as a ‘mandrel’. This is inserted into a metal tube and packed with magnesium oxide powder. This powder has two purposes: it conducts heat, and it electrically insulates the wrapped wire from the tube. The assembly is then compressed further in industrial machinery. This compression is quite a chaotic process: it stretches the wires and joints and deforms the assembly, leading to parts that are not always in spec.

A round heater is an improvement on a conventional heaterblock. It occupies less space, has a lower mass, and focuses heat where it’s needed. This is what we’ve targeted with our HeaterCore. There are some other round solutions emerging on the market already: typically these use the same kind of conventional heater cartridge, but instead it’s bent into a circular shape, so it inherits the same limitations as a conventional heater cartridge.

The Revo HeaterCore is made up of a heater, a sensor, a mandrel, cables, and a retention spring

A round design applies heat evenly and efficiently. The potted assembly is wrapped in a silicone sock to keep the heater stable and protect you from burns

Screen printing is a technique often used to make PCBs or funky t-shirt designs. We’ve applied it to make the metal ceramic heater inside the Revo HeaterCore. Unlike conventional heaters, our design doesn’t rely on nichrome wire at all. Designing it in this way is what makes a positive temperature co-efficient possible.

We take thin-walled alumina ceramic and screen print tungsten paste over it to make serpentine electronic traces. This method is extremely cost efficient, so it’s easy to fine-tune the traces with different arrangements or thickness as necessary to achieve optimal heating – almost like painting heat onto it!

A capping layer of ceramic material is added to protect the printed traces, which are sintered together for greater consistency. Finally, wires are brazed to it (brazing is preferable to soldering as a brazed joint can withstand higher temperatures). The result? An integrated ceramic heater circuit!

Assembly and testing

We produce all the main subassemblies for the Revo product family at our HQ near Oxford, UK. Thanks to all your pre-orders, our team are busy working overtime to ensure we get them shipped to you ASAP.

This machine crimps heater and thermistor wires, for secure, reliable connections

As Revo is our first patented product, we can’t reveal many details about how we make it, but we can talk about QA!

Each HeaterCore is run through a battery of tests to see if it’s been built properly and if it operates as expected. We connect each production batch to our custom-designed test machine, and the serial identifier code is scanned into a database to record the results.

When all channels of the test machine are occupied, the machine starts a test cycle, where it will continuously heat up and cool down. The results are recorded and displayed on the screen: pass or fail.

The test rig uses powerful blower fans to rapidly cool each HeaterCore after a heat up cycle

Looks like we found a lemon!

Because we’ve serialised each HeaterCore, we can trace test data to a specific unit.

If you do have an issue, it’s simple to quote the serial number on the label to our customer service team so they can get to the bottom of things quickly.

Everything that passes QA is fitted with a slick black silicone sock with an embossed E3D logo. We then do a final assembly of the HotEnd – add the heatsinks, fan, fan ducts, pack the products, label them, and store them ready for dispatch all over the world!

Tested Revos ready to be boxed and shipped!

Sanjay explains it all

Anatomy of E3D - Interview with Sanjay

Deep Dive into the E3D Revo Heater

#TCT3sixty interview about Rapidchange Revo