Flame-retardant (FR) filaments are engineered thermoplastics formulated or compounded to slow ignition, reduce flame spread, and limit dripping and smoke. They’re used when printed parts must meet safety standards or reduce fire risk in demanding environments such as electronics housings, transportation components, building interiors, and industrial fixtures.

Why use FR filament

- Safety: Adds time for evacuation and reduces risk of catastrophic spread.

- Compliance: Helps meet standards like UL 94 (HB, V‑2, V‑1, V‑0, 5VB/5VA) required for many electronic and transportation applications.

- End-use readiness: Lets you replace traditional manufactured parts with printed, functional components without sacrificing fire/flame rating.

Common flame‑retardant families and tradeoffs

-

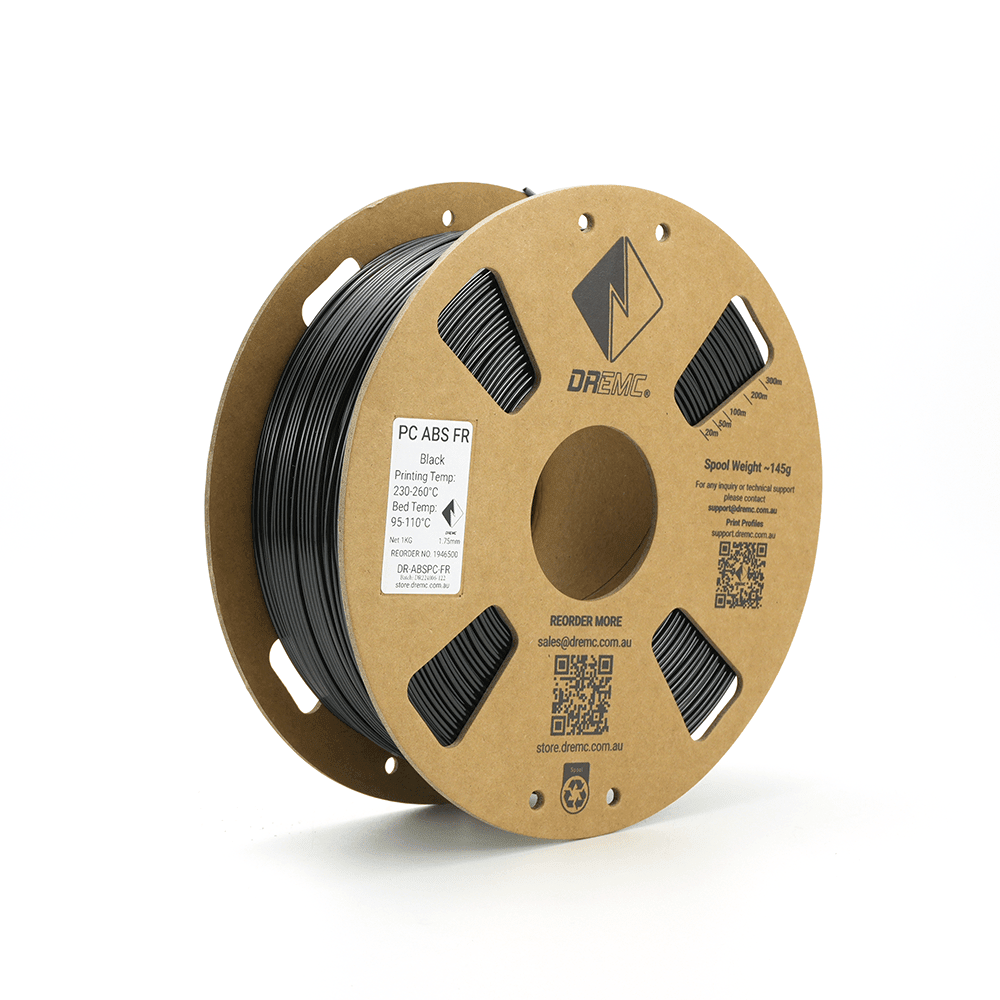

PC‑ABS FR (PC + ABS alloy)

- Strengths: High impact resistance, better thermal performance than ABS, good dimensional stability, available with UL94 V‑0 ratings.

- Use cases: Electronic housings, connectors, enclosures that need structural toughness and flame rating.

- Tradeoffs: Higher print temps (often 265–285°C), require heated bed/chamber and drying; stronger odor—use ventilation/filtration.

-

ABS FR

- Strengths: one lower cost FR blends, similar mechanical properties as ABS (parts design for ABS can be re-printed without too much profile tuning).

- Use cases: Electronics box, structural parts where ABS is preferred with improve HDT but a flame rating is required.

- Tradeoffs: Moderate heat resistance vs PC blends; and still need heated chamber and good bed adhesion.

-

PPS (polyphenylene sulfide) — available with glass‑fiber (GF) or carbon‑fiber (CF) reinforcement

- Strengths: Inherently flame‑resistant, excellent chemical and high‑temperature resistance, very stable (low warp when processed correctly). GF/CF fills boost stiffness, strength, and thermal performance.

- Use cases: High‑temperature, chemically aggressive, or mechanically demanding applications (automotive under‑hood components, industrial fixtures).

- Tradeoffs: Requires very high extrusion temps, hardened nozzle, heated build chamber; abrasive (with GF/CF), higher cost.

DREMC flame‑retardant filament options (summary)

- PC ABS FR — UL94 V‑0 capable, higher heat deflection than ABS, suited for electronics and enclosures requiring toughness and self‑extinguishing behaviour. Print: high nozzle temps, heated bed/chamber recommended; dry filament before printing.

- ABS FR — Easier to print, good mechanical properties with UL94 V‑0 grades available. Use for safety‑critical ABS replacements; heated bed/chamber and ventilation recommended, lower cost.

- PPS (CF / GF) — Inherently flame‑resistant options with superior thermal/chemical resistance; glass‑ or carbon‑fibre reinforced grades for added stiffness. Intended for industrial, high‑temperature applications; needs advanced print setup (high temp, hardened nozzle, drying) but much higher cost compare to other options.

Practical printing tips (applies to FR PC‑ABS, FR‑ABS, PPS GF/CF)

- Use appropriate hardware: hardened/nozzle, all‑metal hotend, and a heated chamber for PC‑ABS and PPS.

- Temperature & bed: follow manufacturer ranges (PC‑ABS often 265–285°C; ABS FR ~220–240°C; bed 100–120°C).

- Dry filament: many FR grades require drying (e.g., 65-80°C for several hours) to avoid print defects.

- Ventilation & filtration: FR filaments can produce strong odors and particulates—print in well‑ventilated areas or use HEPA+carbon filtration.

- Nozzle wear: GF/CF filled grades are abrasive, use hardened steel or Tungsten/Diamond nozzles, our recommendation is using abrasive resistant nozzle to maintain peek performance.

- Design for safety: wall thickness, part geometry, and surface finish affect UL94 outcomes, consult and always test parts for certification as required.

- Check SDS/TDS and certificates: review safety data sheets and UL94 test data for the specific filament batch before use.

Choosing the right FR filament—quick guide

- Need good printability + flame rating for electronics enclosures → PC‑ABS FR.

- Want easier printing with flame retardancy to repalce existing ABS parts → ABS FR.

- Require highest thermal, chemical resistance and stiffness for industrial use → PPS (GF/CF).

Final note

Select the FR grade based on the end‑use environment, required UL rating, mechanical/thermal needs, and your printer’s capability. Always follow supplier printing guidelines, dry and ventilate material properly, and perform validation testing for safety compliance.