Congratulations on diving into the world of 3D printing! Whether your goal is to create functional components, artistic pieces, or quirky gadgets, you are about to embark on a journey filled with creativity, problem-solving, and, yes, a fair share of failed prints. But first, you must tackle a significant decision: should you opt for a prebuilt, out-of-the-box printer, or dive into the complexities of a DIY kit? For 99% of users a pre-built is more convenient as your first machine, but if you're builder or maker at heart or want a project a DIY Kits may be an option.

Let’s break down the pros and cons so you can choose the right path for you.

Ease of Use: Plug-and-Play vs. Build-It-Yourself

Prebuilt Printers: The Easy Route

Picture this: you unbox your new 3D printer, plug it in, run a quick set-up wizard, and within an hour, you're printing your first object. That’s the convenience that comes with a pre-built printer. These are designed with beginners in mind, featuring intuitive interfaces, pre-calibrated settings, and automated functions like bed levelling and filament detection.

Prebuilt printers come with factory-optimised profiles that require minimal user intervention. For many hobbyists and professionals, this means more time spent printing and less time adjusting settings. Although depending which manufacturer printer, you may find there is some filament tuning required for specific materials or parts.

DIY Kits: The Adventure of Building Your Machine

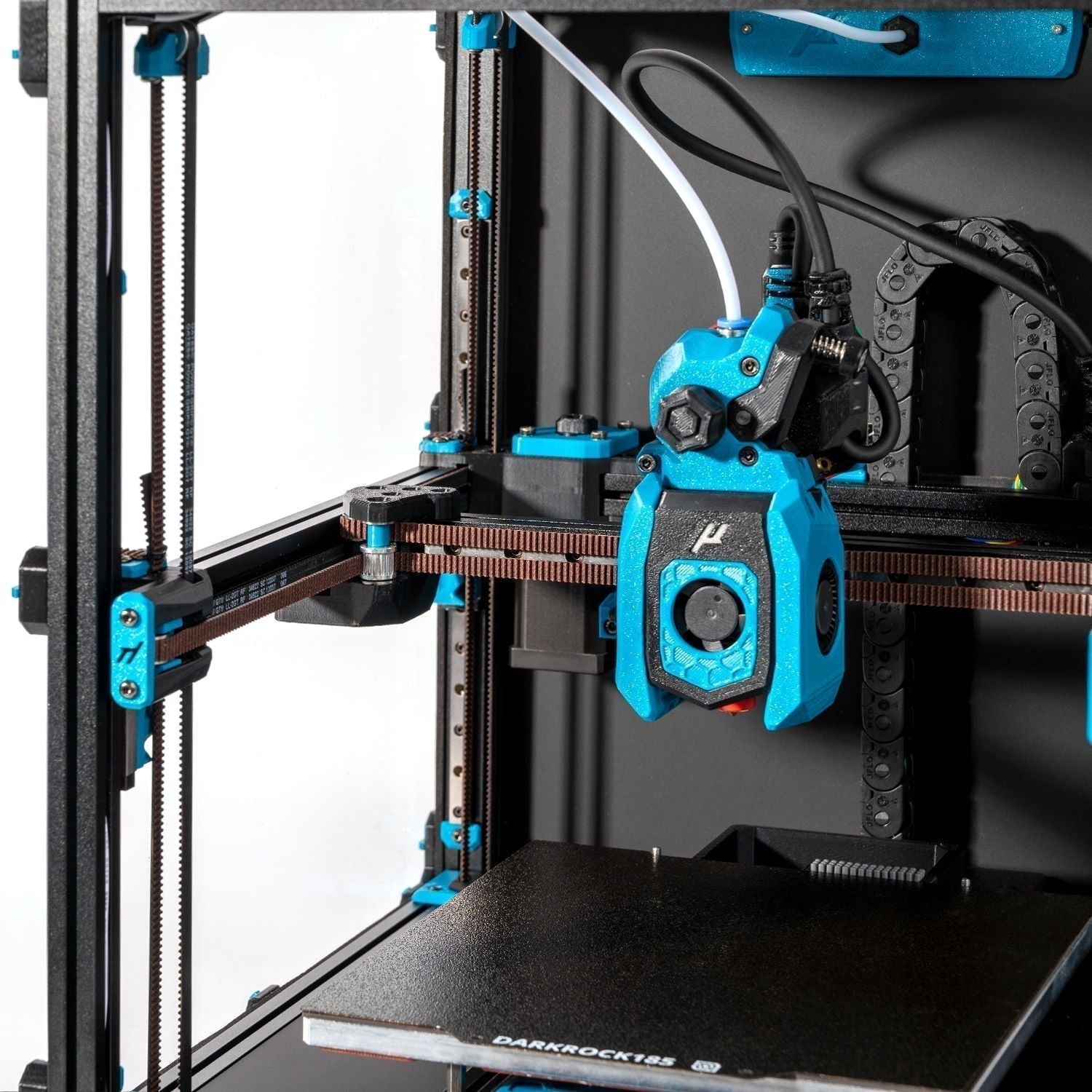

Choosing a DIY kit offers a very different experience. Unlike pre-built models, a DIY kit presents itself as a project. You’ll receive a box filled with components, including screws, stepper motors, frames, and hotends. Assembling your 3D printer is a multi-day endeavour that demands patience, meticulous attention to detail, and sometimes troubleshooting.

The reward? By the time you complete the build, you’ll have a deep understanding of your printer. This knowledge makes future maintenance, upgrades, and repairs significantly easier. Furthermore, the expansive DIY community provides forums, guides, and Discord channels to assist you throughout the process.

Performance: Factory Efficiency vs. Custom Power

Pre-built Printers: Fast and Reliable

In terms of print quality, pre-built printers excel. They are quick, dependable, and capable of producing detailed models with minimal fuss. Features like multi-material support and automatic filament changes enhance your printing experience, especially for intricate projects.

However, this convenience does come with trade-offs. Prebuilt printers operate within a semi-closed ecosystem, ensuring reliability but limiting your ability to customize or experiment with advanced materials.

DIY Kits: Tailored for Flexibility and your dream machine

DIY printers shine when it comes to performance. With their robust frames, enclosed build areas, and modular designs, they handle high-speed prints and advanced materials like polycarbonate, nylon, and carbon-fibre composites exceptionally well. Once properly tuned, a DIY printer can surpass many pre-built models in both speed and quality.

Being open-source, you have the freedom to modify your DIY printer to suit your needs. Manufacturer bust?, you don't worry about that all spare part no longer being made even if its unpopular model. Want a larger build volume? Just swap out some parts. Need a high-flow hotend for top-tier filaments? Go for it! The possibilities are nearly limitless.

Cost: Convenience vs. Investment

Pre-built Printers: Paying for Convenience

Pre-built printers can not the cheapest option; however, you're paying for simplicity and reliability. You're essentially investing in a tool that works straight out of the box, which is invaluable for both beginners and seasoned professionals. There always going to be lower cost machine with questionable reliability, spare part availability or company culture.

DIY Kits: Lower Initial Cost? Higher Time Commitment

While a DIY kit may appear more budget-friendly, don’t forget that you’ll likely need additional tools, materials, and most importantly, time. Constructing a DIY 3D printer requires a significant investment of hours, and missteps could increase your overall costs.

Who Should Choose What?

Pre-built Printers: Best for Beginners and Professionals

Opt for a pre-built printer if you:

- Desire a printer that “just works” with minimal set-up.

- Want to focus more on printing than on tinkering.

- Appreciate a polished, user-friendly experience.

DIY Kits: Ideal for Makers and Tinkerers

Select a DIY kit if you:

- Enjoy building and customising your own tools.

- Seek flexibility for printing with advanced materials.

- Have the patience (and necessary tools) for assembly and calibration.

- Prefer an open-source product that will stay relevant over time.

Final Thoughts

Ultimately, both routes lead to exciting 3D printing experiences. The real question is: do you prefer the straightforward path or the adventurous one and love learn mechanics that goes into printer, essentially do you want be project car or car?