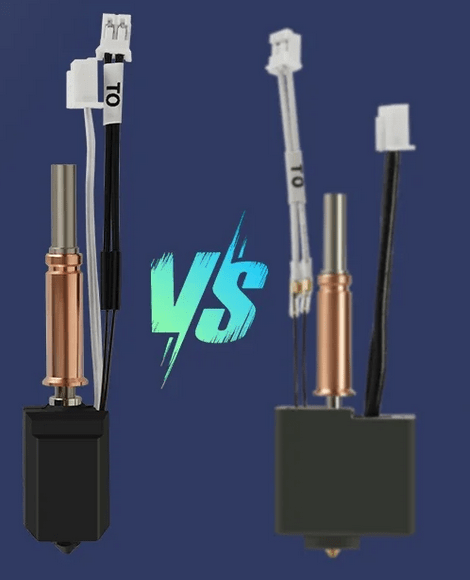

The Anycubic Kobra 3 is an cost effective low-mid-range 3D printer, especially with its multi-material capabilities. But as with many stock hotends for lower-mid end machine, there's always room for improvement, particularly when it comes to the hotend assembly.

Enter the Ceramic Hotend TZ, an after market upgrade promising improved thermal stability, faster heating, and higher-temp performance. But is it worth replacing the stock hotend? Let’s break it down.

1. Build Material & Thermal Performance

Stock Anycubic Hotend:

-

Made with a stainless PTFE heat break and aluminium heater block.

- Lower reliability due to the wearing part (PTFE)

-

Limited thermal insulation means slower heat-up times.

Ceramic Hotend TZ:

-

Constructed with a copper plated heater block for superior thermal efficiency.

-

Heats up faster and maintains temp more reliably at higher speeds.

- All Metal Heat Break (Stainless Steel)

Verdict: Ceramic Hotend TZ wins for thermal performance and no wearing parts like PTFE for the hotend heat break.

2. Print Quality & Reliability

Stock Hotend:

-

Delivers decent print quality with no extra tuning using existing stock provided profiles.

-

Due to PTFE Hotend, the heat break the PTFE over time can degrade and cause print quality issue and leak/clogs jams.

- The Brass stock nozzle is not abrasive resistant and can wear much quicker

Ceramic TZ Hotend:

- All metal heat break design, once assembled correctly it heat break is not like PTFE where its can degrade

- The standard harden steel tip nozzle is abrasive resistant, and less prone to wear compare to the brass

Verdict: Ceramic Hotend TZ offers noticeable gains in print consistency and better reliability with its all metal heat break design and harden steel nozzle.

3. Material Compatibility

Stock Hotend:

-

Works well with PLA, PETG, TPU, and similar.

-

Not ideal for extended high-temp printing (>240°C).

-

Limited compatibility with abrasive or engineering-grade filaments.

Ceramic TZ Hotend:

-

Supports a wider range of filaments including ABS, ASA, Nylon, and composites (when paired with a hardened nozzle).

-

More resilient in high-temperature above 200c over long term compare to stock PTFE hotend.

Verdict: Ceramic Hotend TZ is far more versatile for serious makers.

4. Installation & Compatibility

-

The Ceramic Hotend TZ is designed as a drop-in replacement for the Kobra 3.

Verdict: Installation is straightforward for experienced users, newer assembly have nozzle thread locked, make plug and play but can make difficult when switching nozzle.

5. Value for Money

-

The stock hotend is cost-effective and sufficient for basic use.

-

The Ceramic Hotend TZ, is priced the similar, delivers long-term reliability and performance boosts, especially if you're printing regularly or with advanced materials such as carbon filled materials.

Verdict: Ceramic Hotend TZ is an upgrade for anyone looking to improve reliability, speed, or print with engineering filaments.

Final Thoughts – Should You Upgrade?

If you’re a casual user printing mostly in PLA or PETG, the stock Anycubic hotend will serve you well. But if you're pushing the Kobra 3 to its limits such as using high-temp filaments, the Ceramic Hotend TZ is a smart investment. It improves reliability, and material compatibility, and quick simple direct replacement.