What is a PEI Steel Build Plate and Why Use It?

A PEI (polyetherimide) build plate is a widely used surface in 3D printing, designed to enhance print adhesion and improve overall print quality. PEI is a plastic known for its high thermal stability, chemical resistance, and low friction, making it an ideal choice for build plates.

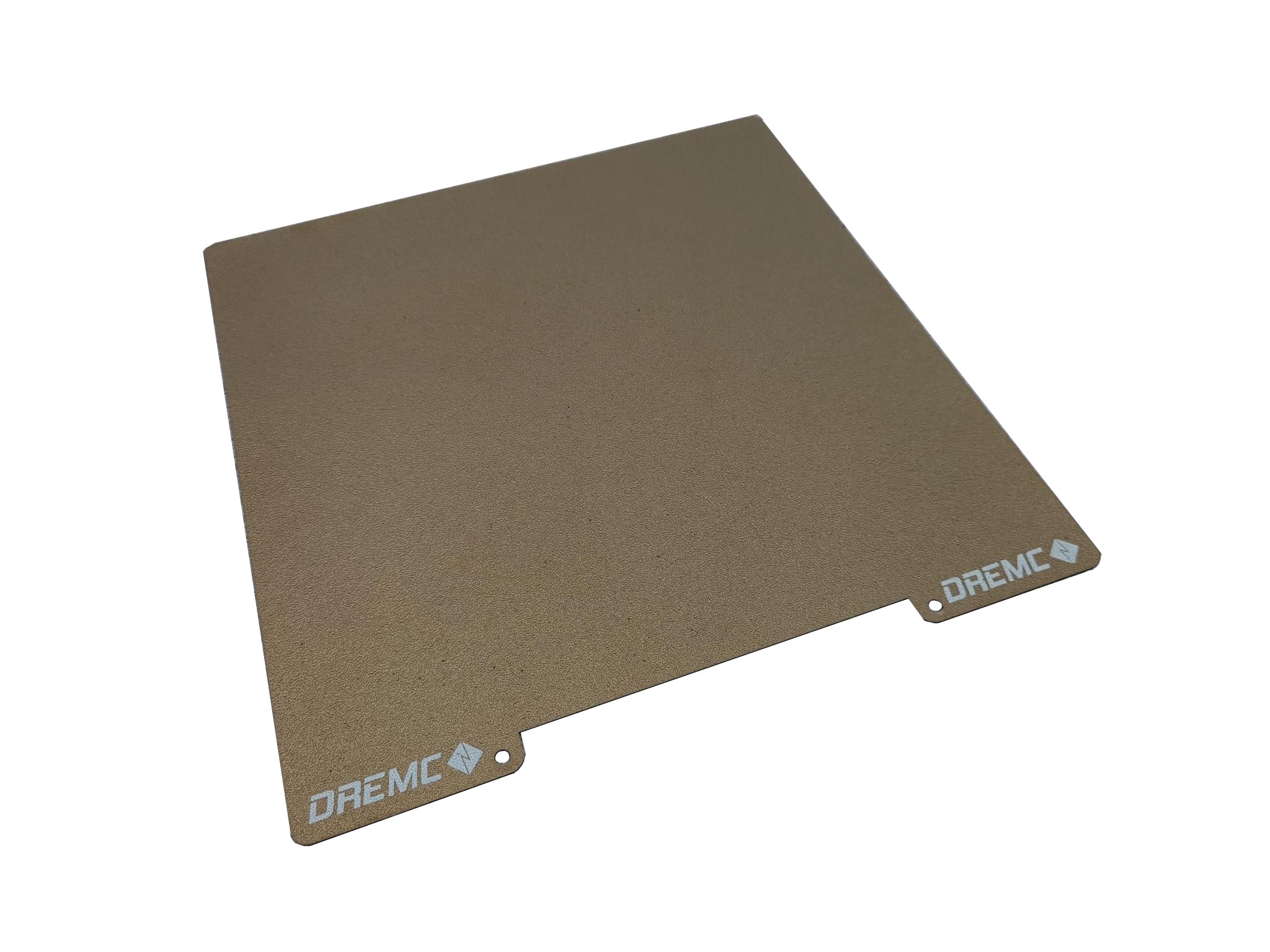

There are usually two types of PEI: one is powder-coated onto the build plate, while the other is a smooth sheet of raw PEI material.

One significant advantage of textured PEI sheets is their ability to provide consistent and reliable adhesion. Filaments like ABS, PLA, and PETG adhere well to PEI without the need for additional adhesives. After printing, objects can typically be removed easily with a scraper or by gently tapping or flexing the build plate. Materials like ABS and ASA, which tend to shrink, will often self-release once the build plate cools to around room temperature.

PEI sheets are also easy to clean and maintain. Due to its chemical resistance, you can safely clean the surface with alcohol or a window cleaner solution to keep it in optimum condition, as removing oils and dust buildup from handling is essential for maintaining bed adhesion properties.

Smooth PEI sheets are applied using a strong, high-temperature 3M adhesive, providing a flat, mirror-like finish that is best suited for PLA without requiring additional adhesives. Other materials may need specific bed adhesives or glue sticks, as they might adhere too strongly and fuse to the surface at elevated temperatures.

In conclusion, PEI build plates offer a combination of durability and ease of use, making them a popular choice among 3D printing enthusiasts and professionals alike. However, it’s essential to consider that while PEI is well-suited for many types of prints, it might not be the ideal option for every filament.

Explore our PEI Ranges suitable for a large range of 3D Printers.